Contact Us

E-mail:

401794711@qq.com

Telephone:

+86-17731108467

Address:

East Shengli Street Road, Yujing West Road, Xingtang County Economic Development Zone, Shijiazhuang City, Hebei Province

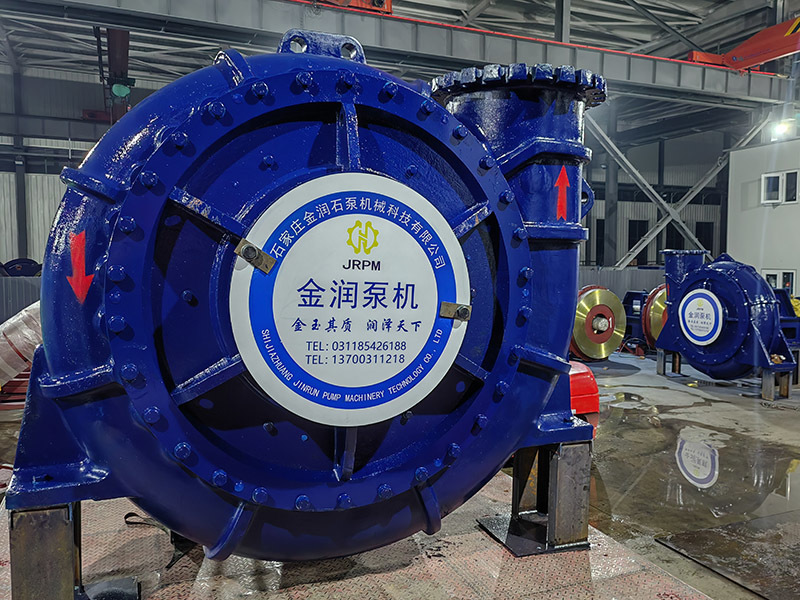

Double shell dredge pump

- Commodity name: Double shell dredge pump

- Product Description

-

The main dredging equipment of the dredger is the mud pump, so the mud pump plays an important role in the dredging work, and the construction of the dredger pump under the optimal working condition can significantly reduce the dredging cost and improve the production efficiency of the dredger.

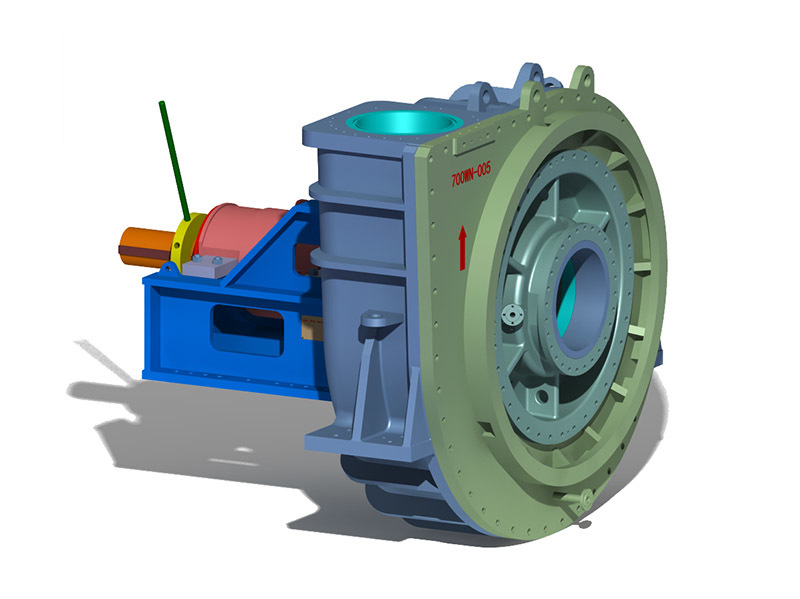

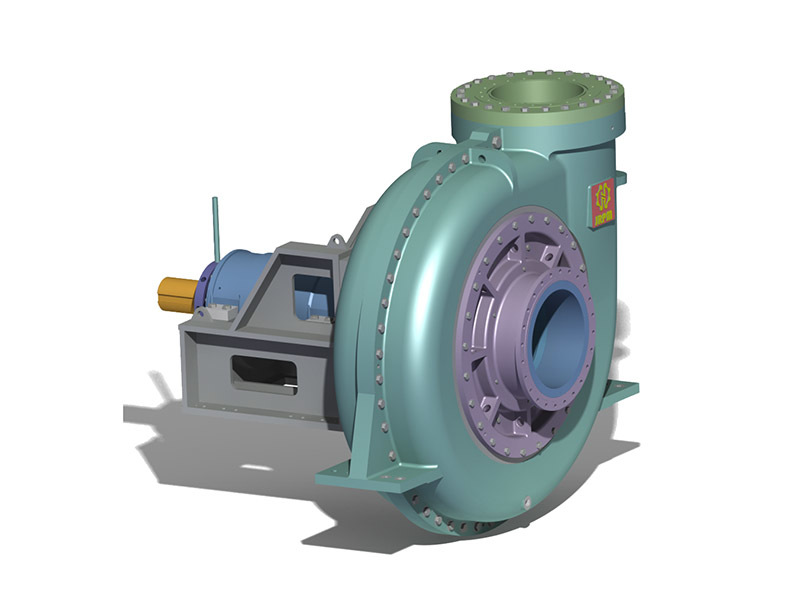

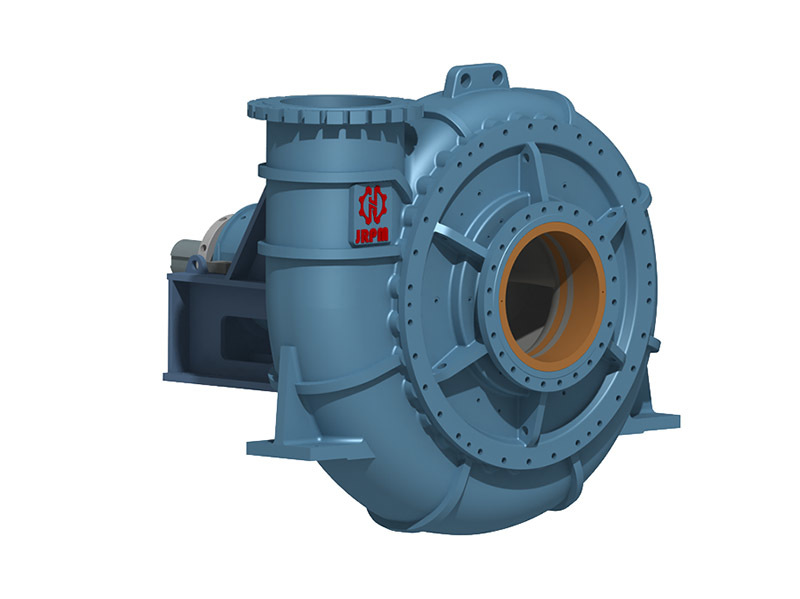

(I), product structure characteristics.

(1) Our company has many varieties of mud pumps with a diameter of 250mm, including single pump casing and double pump casing. It has strong pressure bearing capacity, can meet long-distance transportation, simple structure and easy maintenance.

(2) The diameter 200-500(mm) dredging pump produced by our company uses a single pump casing and a single-stage single-suction cantilever horizontal structure, one type of bracket and the other type of pump box. At present, they are equipped with underwater pumps. When the level 2 or above is connected in series, the pump in the cabin is double pump.

(3) The diameter 600-1200(mm) cabin pump adopts double pump casing (single shell pump), single-stage single-suction cantilever horizontal structure, with bracket, and the lubrication method is forced thin oil lubrication. The underwater pump adopts a single pump shell structure to reduce the pump weight and facilitate the lifting and moving. The front disassembly type is equipped with special tools, which is easy to disassemble and repair.(II) and product advantages

1. Good dredging performance.

(1) good cavitation performance, to ensure that the pump on the ability to suck, while reaching a greater depth and higher inhalable concentration.

(2) the impeller flow channel width, flow capacity is strong.

(3) the performance curve drops sharply, so that the mud pump has a stronger adaptability to the change of the row distance.

(4) by changing the pump speed, or changing the impeller diameter can achieve a variety of pump performance deployment.

2. Good wear resistance and long life of overcurrent parts.

(1) The impeller, sheath, lining plate and other over-flow parts adopt strong anti-wear alloy cast iron, which has strong impact resistance and high anti-wear performance.

(2) In the product design process, the service life matching between parts is fully considered, and the replacement cycle of wear-resistant parts is basically the same, which reduces the maintenance and replacement cost.

3, small hydraulic loss, high efficiency, good economic performance.

Due to the advanced hydraulic model, the efficiency level of the mud pump is high, with an average of more than 5 percentage points higher than other mud pumps, so that the fuel consumption is lower at the same output.

4. The shaft seal is reliable and has no leakage.

Diameter 200-500(mm) dredge pump shaft seal using mechanical seal, packing seal, composite seal. Diameter 600-1200(mm) dredge pump shaft seal adopts screw sleeve L-shaped rubber seal, the sealing device oil 3 L-shaped sealing ring and a threaded shaft sleeve composition. In order to improve the life of the shaft seal, a sand water separator is equipped to ensure the quality of the shaft seal water.

5. The bearings adopt domestic and imported SKF and FAG bearings, with the forced lubrication system and intelligent alarm system developed by our company to ensure the life of the bearings and the monitoring of the operating conditions of the bearings.

Key words:

Get Quote

Note: Please leave your contact information and our professionals will contact you as soon as possible!