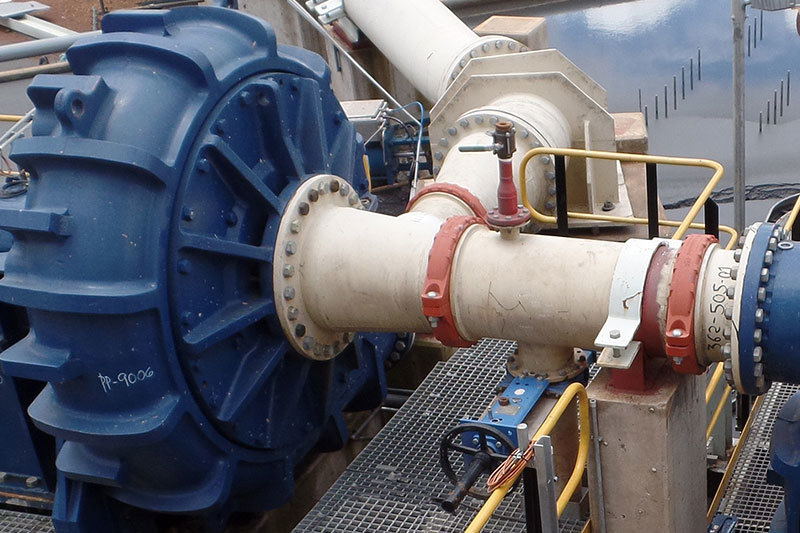

Why is the slurry pump noisy and what is the solution?

The pump is caused by metal objects or other objects, or the impeller and the pump casing friction, the solution is to disassemble the pump body to check and eliminate friction.

2023-09-25

Some users in the use of various types of slurry pump products will appear slurry pump vibration phenomenon and noise, the following to share the reasons for the noise and slurry pump noise solution, for your reference.

1. Cavitation phenomenon: Most of the reasons for the noise of slurry pump in newly installed slurry pump products are installation problems. For example, the inlet and outlet pipelines are not installed according to the standard caliber but the caliber of the pipelines is increased. Before the cavitation phenomenon occurs in the slurry pump, the vibration of slurry pump is accompanied by the noise of slurry pump, which can be solved by closing the small outlet valve or changing the caliber of the pipelines.

2, rotor imbalance: slurry pump rotor or drive rotor imbalance, this situation should be rebalanced by the rotor.

3, correction coupling: horizontal multi-stage slurry pump contains the coupling due to the pump shaft and motor shaft in the poor, mechanical vibration and noise is larger, the solution is to recalibrate the coupling.

4, bearing wear is serious: bearing wear is too serious, resulting in excessive clearance, should be replaced with a new bearing.

5. Loose foot bolts: For loose foot bolts or the reason why the foundation is not firm, check and tighten the loose parts or replace them.

6. The liquid level is lower than the pump: For example, when the liquid level of the horizontal slurry pump product selected by the user is lower than the pump, the horizontal slurry pump is empty due to the lack of bottom valve installed in the inlet pipeline. In this case, the bottom valve tank should be installed to take water after starting the pump, or it is more appropriate to switch to the self-priming slurry pump.

7. Loose parts of slurry pump: Long-term work causes loose or damaged parts of slurry pump, tighten loose parts or replace them.

8. Pipes supported by mud pumps: The support is not strong or the pipeline is supported by the pump. The solution is to strengthen the pipeline support and should not rely on the pump to support the pipeline.

9, slurry pump and metal objects contact: the pump into the metal objects or other objects caused by, or impeller and pump shell friction, the solution is to disassemble the pump body check to eliminate friction.

Key words:

Next:

Related News

Contact Us

E-mail:

info@cnjrpm.com

Tel:

+86-311-85426188 / 85426588

Phone:

+86-17731108467

Address:

East Shengli Street Road, Yujing West Road, Xingtang County Economic Development Zone, Shijiazhuang City, Hebei Province